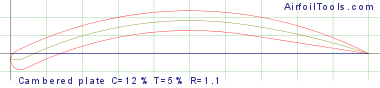

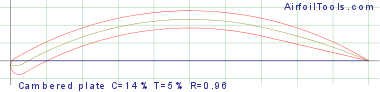

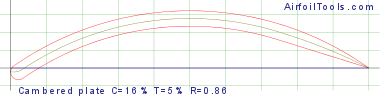

Generated airfoil shapes

Cambered plate airfoils

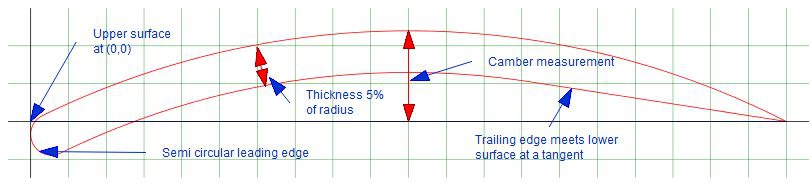

A simple and effective way of making blades for small wind turbines is to cut the blades from sections of metal or PVC pipe. The angle and twist of the blade can be controlled by the shape of the cut and the curve of the pipe approximates to an airfoil shape. When the airfoil is normalised, the camber and thickness of the blade depends on size of the section through the pipe. The following parameters are used to model a typical section.

- The wall thickness of the pipe is 5% of the radius.

- The leading edge is semi-circular.

- The camber is based on the top surface (outer radius of the pipe).

- The trailing edge is sharp and cut away at the bottom of the airfoil until it meets the lower surface at a tangent.

- The top surface is used as the datum and passes through the points (0,0) and (1,0). This is not correctly normalised but in practice it is easier to mark out the shape on the surface of the pipe.

Examples in the database

| cp-060-050-gn | 6% |  |

| cp-080-050-gn | 8% |  |

| cp-100-050-gn | 10% |  |

| cp-120-050-gn | 12% |  |

| cp-140-050-gn | 14% |  |

| cp-160-050-gn | 16% |  |